What Makes DL Your Ideal Partner

QUALITY ASETY

We have a professional customer service team to answer your doubts at any time.

UNIQUE DESIGN CONCEPT

Provide the most excellent products,the most favorable price.

Step inside the precision-driven world of our factory

Mold Maintenance Workshop

Precision Inspection Workshop

Construction Equipment

Automated Assembly Workshop

Mining Equipment

Welcome to DL

DL MOLD

DL has 200 employees, and own different kinds of imported precision machining, production, processing equipment and testing experimental equipment. It meets the mold business demand with an output value of 200 million RMB for mold making(about 700 sets) , and 300 million RMB for injection molding production and assembly business.

Browse our Catalog

Request a Quote

Reliable Delivery

Easy Returns

Modern Mold Manufacturing and Injection Molding.

Our Main Services

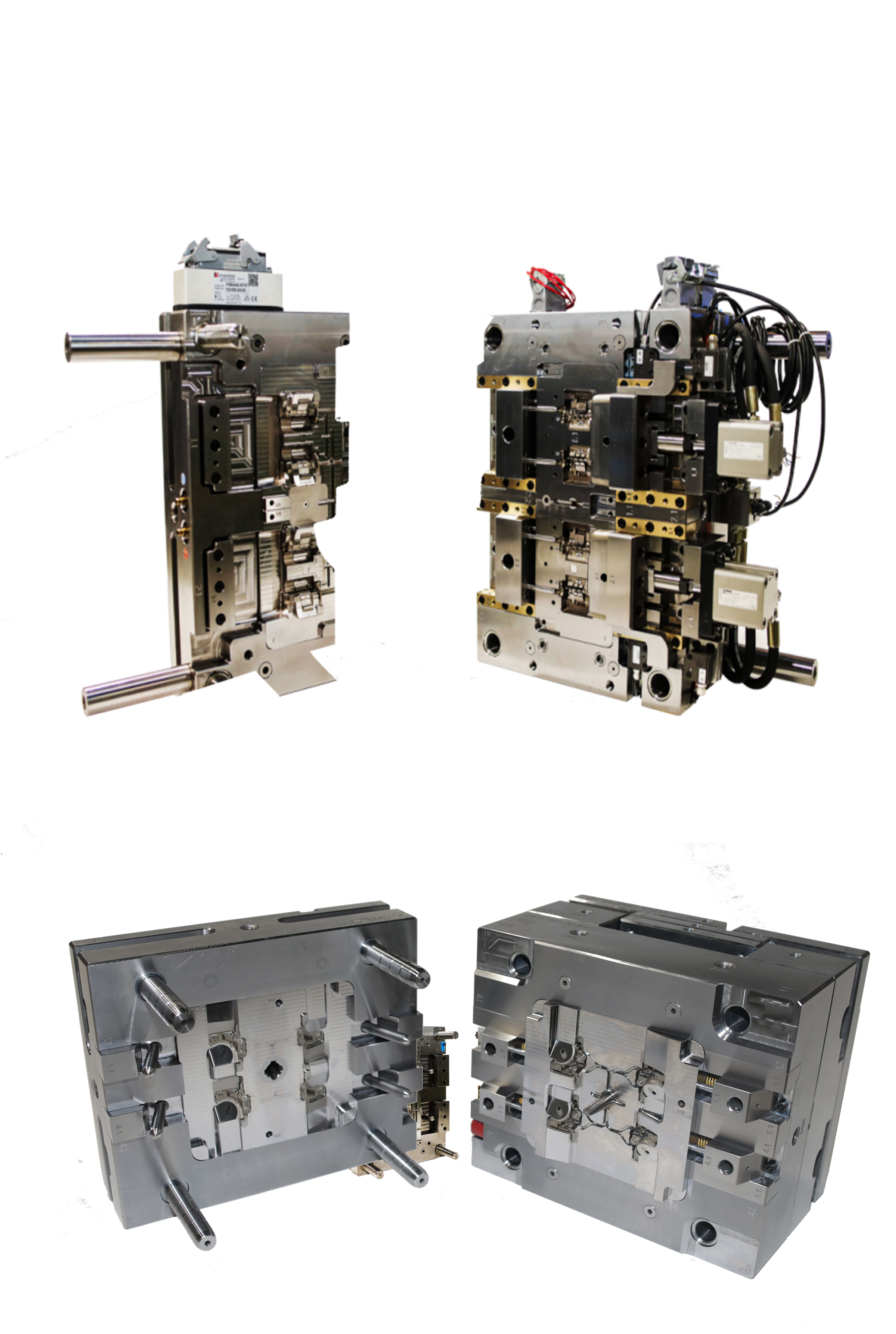

Mold Design & Manufacturing, Injection Molding Production

Our expertise in Mold Design & Manufacturing and Injection Molding Production stands as the backbone of our industrial services, offering comprehensive solutions from conception to completion.

Component of Wiring,Product Assembly

we handle the intricate processes of Component of Wiring and Product Assembly, ensuring that every electrical component is perfectly integrated and every product is assembled with meticulous attention to detail.

Packaging Ect One Stop Service

We streamline the process, ensuring your products are market-ready with efficiency and ease, providing a seamless experience from start to finish.

Examples of Development Case

【Mold type】 Precision transparent plastic molds, high precision molds, and etc.

【Capacity】 Could manufacture up to 50 sets of this kind of molds per project

【Customer】 David, Kitron, BD, and etc.

【Mold type】 Multiple cavities molds , molds with interchangeable inserts, and etc.

【Capacity】 Could manufacture up to 50 sets of this kind of molds per project

【Application field】 Automobile, Aerospace, Railway, Communication, Home application and etc.

【Mold type】2K molds, 3K molds, high gloss molds for appearance functional parts 【Capacity】 Could manufacture up to 60 sets of this kind of molds per project 【Customer】 Joyson 、 ITW 【Car type】 Mercedes, BMW, Porsche, Volvo, VW, GM, Toyota, FIAT……

【Mold type】 Zinc die casting molds, Insert Injection Molds.

【Capacity】 Could manufacture up to 60 sets of this kind of molds per project

【Customer】 HUF, Valeo, ……

【Car type】 Mercedes, BMW, Porsche, Hyundai, VW, Audi, Mazda…..

【Mold type】 2K molds, Gas assistant Molds, Insert Injection molds

【Capacity】 Could manufacture up to 60 sets of this kind of molds per project

【Customer】 HUF

【Car type】 Hyundai, VW, Audi, Mazda…..

Check Out our Most Recent Articles

A: DL provide services include mold design & manufacturing, injection mold, injection production parts, electronic design &

manufacturing, PCB layout, PCB assembly, prototyping, SMT & DIP, through hole assembly, material procurement, CNC machining,

product assembly, packing ect services.

A: We are able to accept STEP, STP, IGS, STL, X-T files.

A: In general, it will take 2-4 weeks, depending on the complexity and cavity Number of the mold. And 15-30 business days for mass

production.

A: We enable our customers to reduce their operating costs and delivery requirements by taking advantage of our professional

design, manufacturing, procurement knowledge and experience. Yes. our engineers provide assessment of existing designs and assist

in new designs to optimize manufacturability (DFM), minimizing costs and achieving quicker time to market.

A: We have an independent quality department to check every step by IQC, IPQC, OQC.If there are any defective items we willl take

corrective action to ensure the elimination of the root cause of defects. When you get the goods and find there is a defect after

check. We promise to accept your asked return at our cost or provide replacement free.

A: Your files are held in complete safety and security.We protect the intellectual property for our customers in the whole

process.. All documents from customers are never shared with any third parties. We are willing to sign NDA effect by customer side

local law and promising to keep customers data in high confidential level.

Call Now

123-234-1234

Time Operasional

09.00 AM - 05.00 PM

Location

Indonesia, Pku